Frequently asked questions

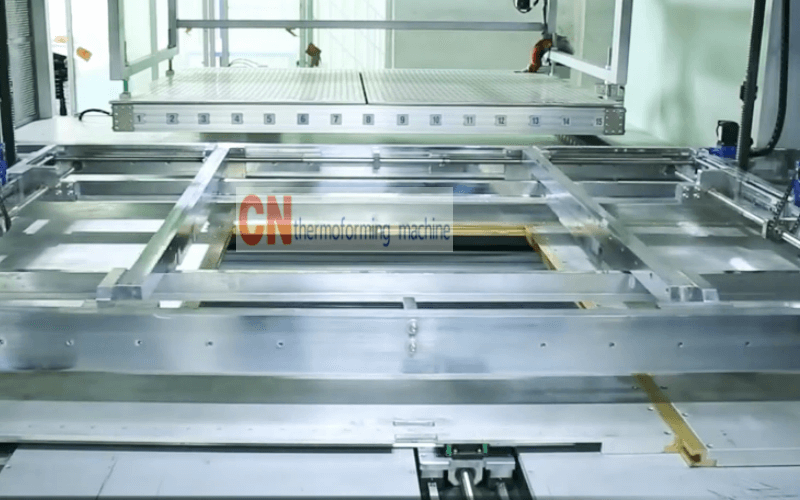

What Are the Machine’s Forming Capabilities?

Our heavy-gauge thermoforming machines offer a maximum forming area up to 4500 × 2000 × 1000 mm and can process sheet thicknesses from 1–15 mm.

They are suitable for a wide range of materials — ABS, HIPS, PETG, PMMA, HDPE, PC, and PP — and ensure precise forming quality even on large automotive and industrial parts.

Optimized heating and vacuum systems guarantee uniform thickness and high surface quality.

How Advanced Is the Control and Automation System?

All CN Thermoforming machines are equipped with PLC + servo control for accurate motion and repeatable forming cycles.

Automatic sheet clamping, mold adjustment, and servo-driven platen movement help achieve faster cycle times and stable operation.

We also provide robotic loading and unloading options for fully automated production lines.

What Kind of After-Sales Service Is Provided?

We offer comprehensive global after-sales support including:

On-site installation and operator training.

24/7 online technical assistance via video call or remote PLC access.

Spare parts supply within 48 hours.

One-year warranty and lifetime technical support.

Our engineers have decades of thermoforming experience to help customers maximize uptime and production reliability.

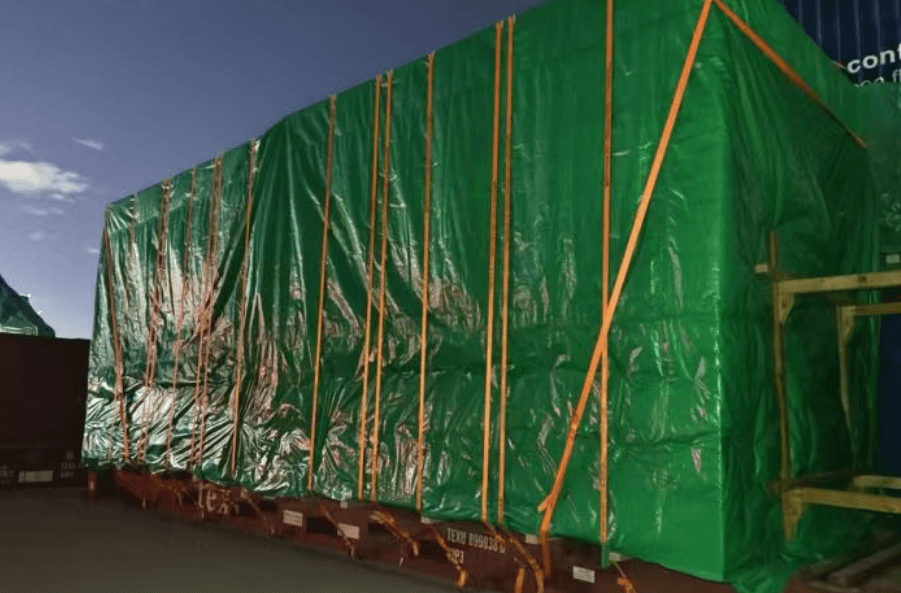

How Experienced Is the Manufacturer?

With over 15 years of thermoforming experience and machines exported to more than 30 countries, CN Thermoforming Machine has built a strong reputation for reliability and innovation.

We serve global customers in the automotive, transportation, and packaging industries, providing turnkey solutions from mold design to production setup.

Customer success stories from Thailand, Australia, and Europe prove our technology’s stability and efficiency.

Can I Test My Product Before Buying?

Absolutely. We welcome customers to send molds or sample sheets for testing at our factory.

We’ll provide video demonstrations, forming samples, and detailed process reports — helping you evaluate heating performance, mold fit, and forming quality before final purchase.

Can the Machine Be Customized for My Products?

Yes. Every CN thermoforming machine is custom-built based on your product dimensions, forming depth, and material characteristics.

We design the mold clamping system, heating layout, and vacuum flow to match your specific part requirements — whether for automotive bumpers, appliance covers, or medical trays.

If you already have molds, we can adapt our system to ensure full compatibility.

we don’t just sell machines — we deliver complete thermoforming solutions tailored to your production needs.

our goal is to help you produce better, faster, and more efficiently.

Contact Us Now!